Paper Technology

HOME >> PAPER TECHNOLOGY

PAPER TECHNOLOGY

Scan Machineries are pioneers in Pulp and Paper Technology. We are involved in designing and manufacturing high end quality Pulp and Paper Machinery which is our bread and butter in the Paper Industry. Our main objective is to assist and lead our valuable customers into creating a high quality end paper product that is sought after in the market. We walk amongst you throughout this journey every step of the way while empowering sustainable energy through our Paper Making process.

Scan Machineries helps you in designing your own Paper Mill and guides you where you as a customer stands out from other paper manufacturers with a niche and unique paper product for the market. Our scope would begin right from the Pulp Mill through the approach flow system to the beginning of the Paper Machine, headbox all the way to the winder.

The technology involved in Paper Machine

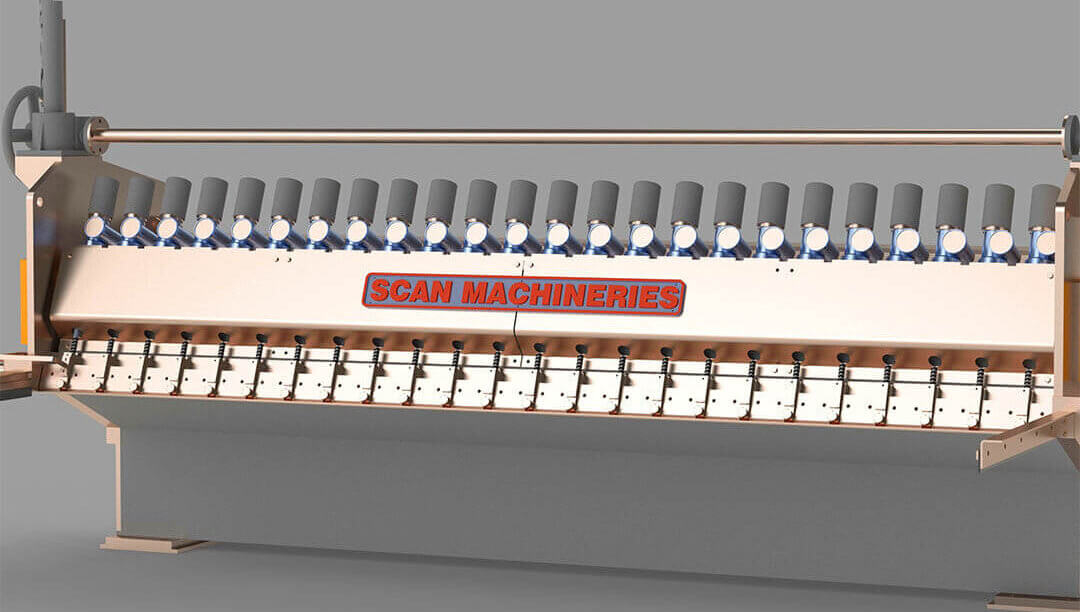

The headbox is the first section of Paper Machine which is located in the wet end or wire part section. The pulp is pumped to the headbox from the machine chest which is then followed by going through a number of sections inside the headbox involved in creating turbulence and consistent flow onto the wire. The wire then carries the pulp containing water of 99-99.7% consistency and is passed through a series of vacuum foils which sucks the water out the pulp respectively. The pulp sheet is then passed through a number of paired rolls located in the press section which causes a nip pressure or load onto the sheet thereby squeezing the water out of the pulp. The pulp sheet is then moved to a dryer section which consists of an array of drying cylinders which is filled with steam at a high pressure and temperature that evaporates the water from the pulp and is then coated with a sizing solution and is again dried forming a coated paper.

This paper is then passed through a calender which maintains the glossiness of the end paper product. The paper is wound onto an empty spool in the pope reel section till the paper is of a large diameter namely the parent reel. This parent reel is then placed on a winder machine which cuts the paper reel into the desired shape and size while maintaining the tightness or tension of the wound up paper. They are then transported to different parts of the world and is again put in converting systems that finally reaches you as an end consumer.

Recycled Paper Making Process by Scan Machineries

GET MORE INFORMATION

Our team is looking forward to undertake your new Turnkey Paper Machine project.

Contact us: sales@scanmachineries.com