Paper Machine Headbox

HOME >> PAPER TECHNOLOGY >> PAPER MACHINE HEADBOX

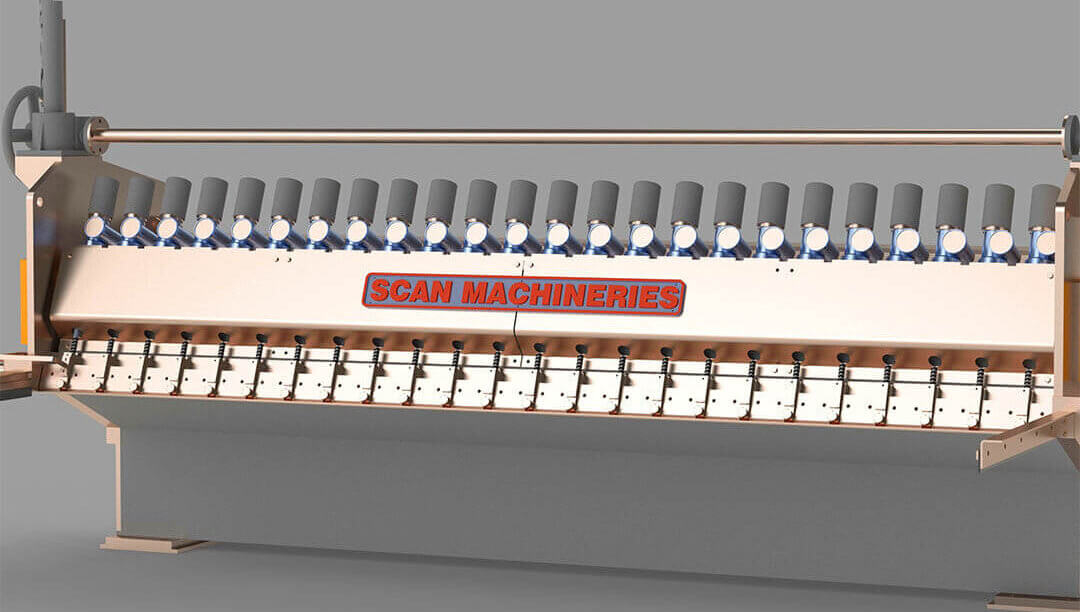

Hydraulic Jet Headbox

The hydraulic dilution profile headbox of Scan Machineries combines the highest paper quality with low energy costs. Paper quality is improved and at the same time allows substantial savings in energy costs for our customers. Precise cross profiles of grammage (CD profile) are maintained and fiber orientation is ensured. All internal surfaces in contact with the stock flow are finely polished. Turbulence generators are combined with tube banks and nozzles for efficient operation and excellent runnability. Finest manufacturing precision and unique macro adjustment along with our high precision dilution profile injectors provides the highest paper quality and properties.

The slice lips are motorized to adjust the slice gap between the lips and for controlling the output of stock flow. All internal surfaces in contact with the stock flow are finely polished. Excellent stock dispersion from the headbox ensures the best sheet formation.

Passion for Paper

SCAN MACHINERIES

Your Headbox Project Partner

Our dedicated and well experienced team for the Pulp and Paper Industry undertake Hydraulic Jet and Pressurized Headbox Projects for clients across the Globe looking to set up a new Paper Mill or rebuild their existing old headbox. Guaranteed optimal performance and end results in both your paper sheet properties and runnability right after startup of headbox.

- Enhanced visual appearance

- Better cross profiles CD & MD

- Uniform stock distribution

- Improved paper quality

- Increased machine productivity and runnability

- Unform grammage profiles GSM with optional dilution control

- Fewer web breaks

- Best sheet formation and fiber orientation

- Provides highest value for your paper grade

Undertaking Projects from 50TPD to 500TPD+

Function of paper machine headbox

The Headbox is designed to distribute a continuous flow of wet stock across the width of the machine and lengthwise as stock is deposited on the screen at constant velocities. Stock should be properly dispersed over all areas of the sheet-forming surface in equal quantities. The early headbox, more commonly called a flow-box or breast-box, consisted of a rectangular wooden vat that extended across the full width of the machine behind the fourdrinier breast roll.

Scan Machineries Paper Machine Headbox line can meet all customer needs in terms of production, quality, and application. We design and manufacture Hydraulic Jet Headbox, Air Pressurized Jet Headbox, and Open Type Headbox.

Scan Machineries Headbox provides an Excellent Sheet Quality

Scan Machineries Headbox – The best solution to achieve an Excellent sheet formation with minimum Energy consumption

Benefits of Headbox

A well-constructed headbox will provide many benefits:

It can improve formation and paper quality, reduce number of breaks and downtime, fewer pinholes, dirt spots, improve runnability, increase machine speed. stabilized paper caliper, improve water removal, and reduce chemical cost.

All these properties are achievable, if the CD basis weight profile, main fiber direction, uniform formation, flatness, etc. are perfect.

Paper Machine Headbox Requirement Form

To get a quick reply and quote, fill out the following form. Our sales team will reach out to you shortly.

Board and Kraft Paper Machine

Scan Machineries is a leading Complete Paper Machine Manufacturer for the production of Kraft Paper, Writing and Printing Paper, Tissue Paper, Specialty Paper, Packaging and Board grades...

GET MORE INFORMATION

Our team is looking forward to undertake your new Paper Machine Headbox project for your Paper Mill.

Contact us: sales@scanmachineries.com