Press Section

HOME >> PAPER TECHNOLOGY >> WET END >> PRESS SECTION

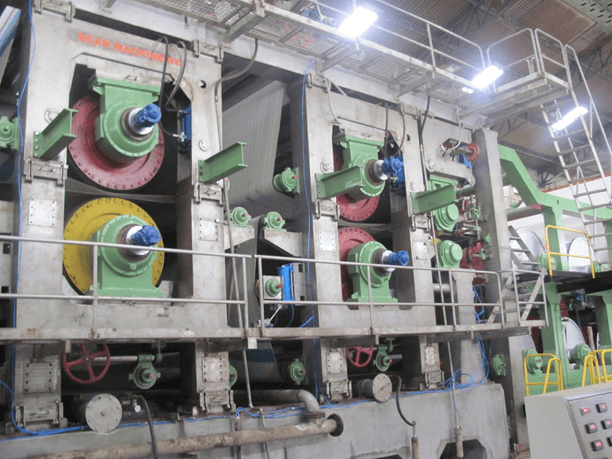

Paper Machine Press Section Manufacturer

Scan Machineries is the one of the leading paper machine manufacturer in Coimbatore, India. Over 30 years experience in the Paper and Pulp Industry. We engineer design and manufacture the Paper Machine Press section. All types of Press section Jumbo Press section, Bi-Nip Press section, Tri-Nip Press section, and Straight through Press. Paper Machine Press section remove water by wet pressing thereby increasing the dryness of sheets in order to ensure adequate paper machine drying capacity and improve web runnability at the beginning of the dryer section. As the sheet of paper is formed, some of the free water contained within it is removed by the press section. This increases the solids content of the sheet. Mechanical dewatering of thee paper web is the main function of the press section. As well as determining smoothness and two-sidedness, the press configuration affects surface properties.

Press Section - Jumbo Press Manufacturer

Jumbo press roll usually refers to a nip that has a diameter of more than 1000mm and is made up of pressing rollers. In the manufacture of corrugated paper, cardboard, and other pieces of paper or cardboard with large basis weights, it is widely used. The large-spoke press provides a wide nip that can hold the paper sheet for a long time, compared to ordinary presses. Using the two-way vertical dehydration design, it can improve dehydration efficiency, increase dewatering capacity, and increase paper quantity. The dryer section can also be reduced in steam consumption, which in turn reduces production costs. The paper will also be stronger and more burst resistant. When the paper machine is running, there will be a large amount of heat between the rollers due to the large linear pressure between the rollers and the high load. Water was added to the side of the operation shaft head in order to cool the circulating water, which protected the surface coat rubber. Paper machines with this technology typically offer high speed, low energy consumption, and good paper quality. In order to speed up and save energy on old paper machines and design new ones, jumbo pressing technology and equipment have become the first choice.

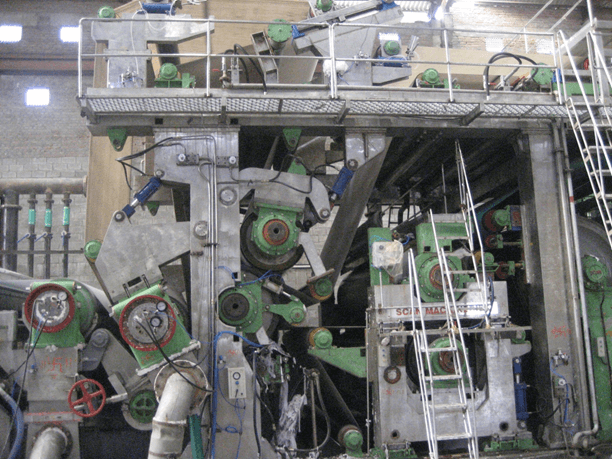

Bi-Nip and Tri-Nip Press section Manufacturer

Scan Machineries is highly rated in offering Bi-Nip press section to the our customers. Offered wide range is made by a team of veteran professionals using top quality material following the norms and guidelines laid down by the industry. Press section is checked on various quality parameters before final dispatch in the market. Offered range is widely acclaimed by client for high strength and optimum quality.

Easy to install high quality robust construction. Our press sections are designed for high speeds and with the nip for removal of water. The Press section also has motorized or manual stretchers with improves the handling of the felts. The Bi-Nip press is provided with twin doctor mechanism with pneumatic loading system for better doctoring of the rolls.

Features:

- Closed draw Bi-Nip Press & Tri Nip Press

- Wide Nip Press up to 400 KN / M

- Press concept with 1500 dia roll with wider Nip.

- Motorized stretchers for high speed machines.

- Air tube flexible doctors for single & double doctoring.

GET MORE INFORMATION

Our team is looking forward to undertake your new Paper Machine Press section project for your Paper Mill.

Contact us: sales@scanmachineries.com