Follow us on!

Copyright ©2021 Scan Machineries Pvt Ltd. All rights reserved

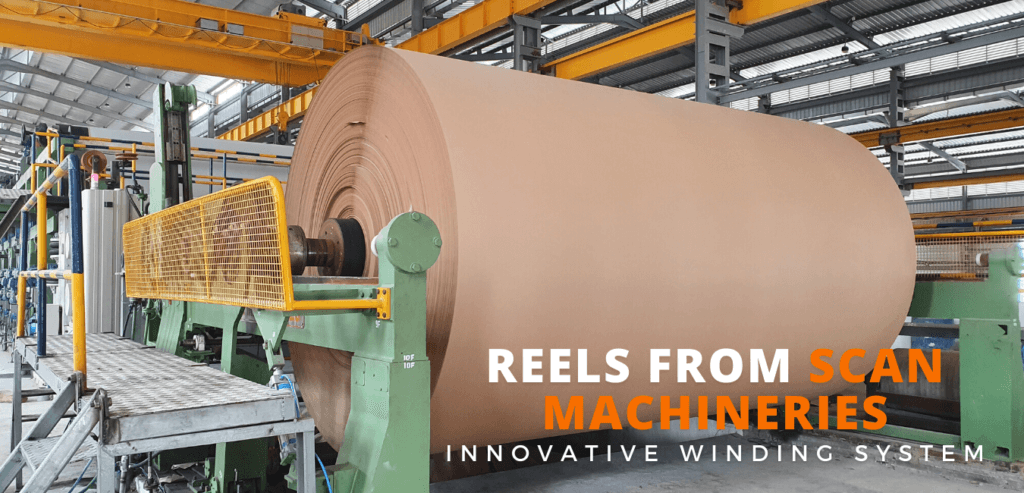

Winding/Reeling

HOME >> PAPER TECHNOLOGY >> WINDING/REELING

In the Paper Machine, the paper is rolled up in reels, which facilitates it's transportation and use in subsequent operation. These reels are called Jumbo Rolls and they wound on tambour rolls and then sent for cutting and Rewinding. Pope Reels made from heavy-duty steel framing and a hydro pneumatic system, are of excellent quality.

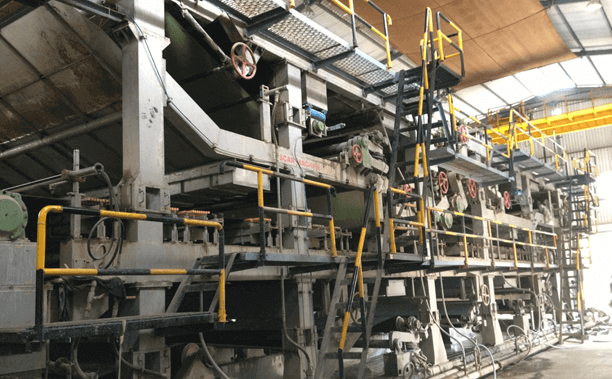

Winders are used to convert large diameter, machine-width paper or board reels made by a paper or board machine inti finished roll sets that can be converted or shipped. The winder slitters are used to cut parent reels(Pope Reel) into various widths and to trim the edges will be explained in this module, as well as safety guidelines for winder slitters and slitter sections.

A paper manufacturer primarily uses two types of winding: The process of winding and reeling. At the dry end of a paper machine, reeling produces very large rolls of paper or board, called "Parent reels". During winding, large parent reels produced on a paper machine are converted into customer sized rolls ready for conversion or shipping.

To get a quick reply and quote, fill out the following form. Our sales team will reach out to you shortly.

Scan Machineries is the Best Manufacturer for Paper Machine. Scan Manufacturing Various type of Fourdrinier that is Single Wire, Double or Twin Wire and Multi Wire.

Our team is looking forward to undertake your new Paper Machine Winding/Reeling project for your Paper Mill.

Contact us: sales@scanmachineries.com

Follow us on!

Copyright ©2021 Scan Machineries Pvt Ltd. All rights reserved