Paper Mill Winder

HOME >> PAPER TECHNOLOGY >> WINDING/REELING>> PAPER MILL WINDER

Paper Slitter Rewinder and Winder Machine Manufacturer

"Every winding needs the Perfect Winder"

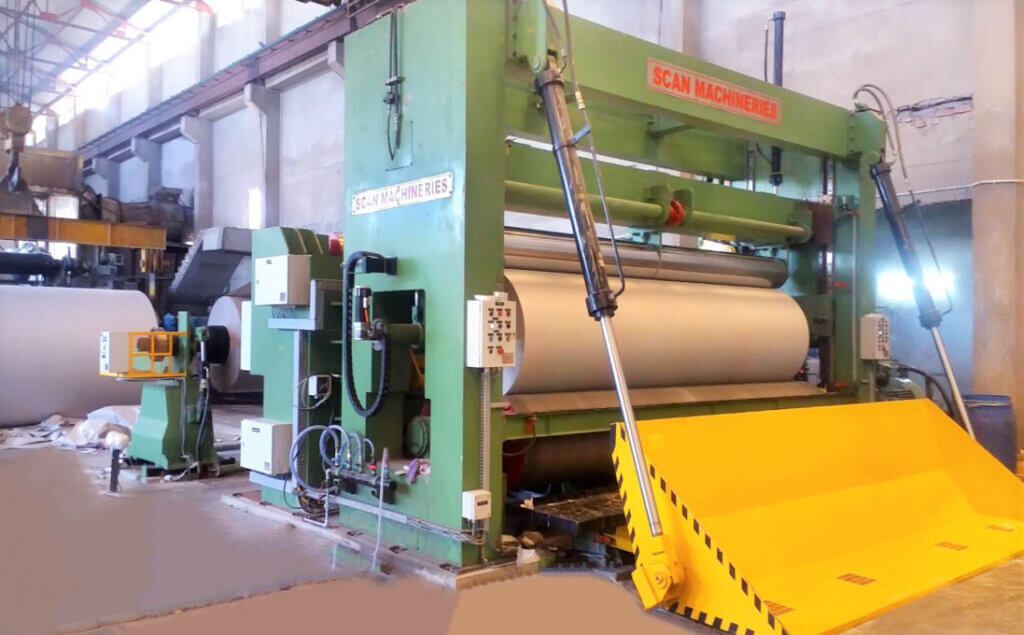

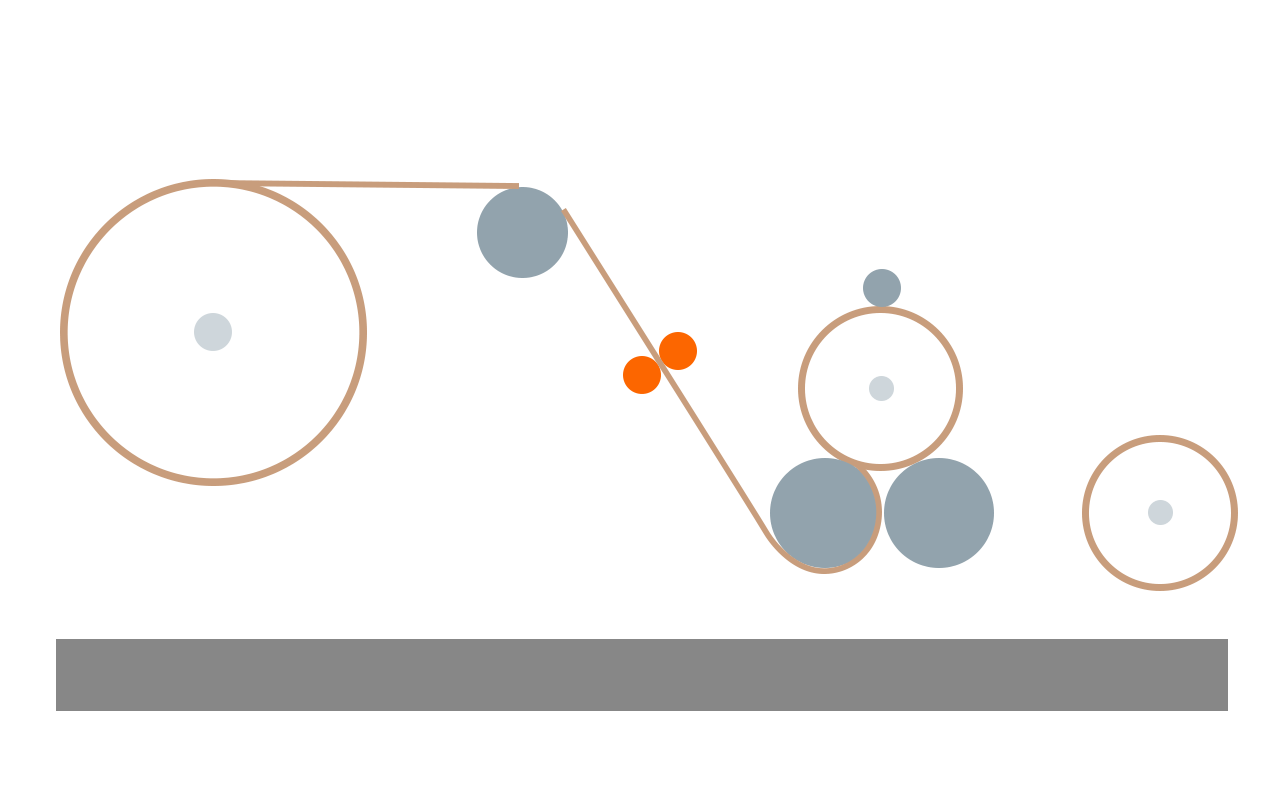

Scan Machineries Winder and Rewinder is based on the latest two-drum winder technology. Our high speed paper machine winders and rewinders are used for winding for a wide range of Paper and Board Rewinder, Writing and Printing Paper Rewinder, and Tissue Paper Rewinders. We engineer, design and manufacture the winders in our own facility through our unique production lines. Our winders provide excellent quality and winding of wound up daughter reels from the parent reel of the Reeler also known as the pope section.

What does a Paper Machine Winder do?

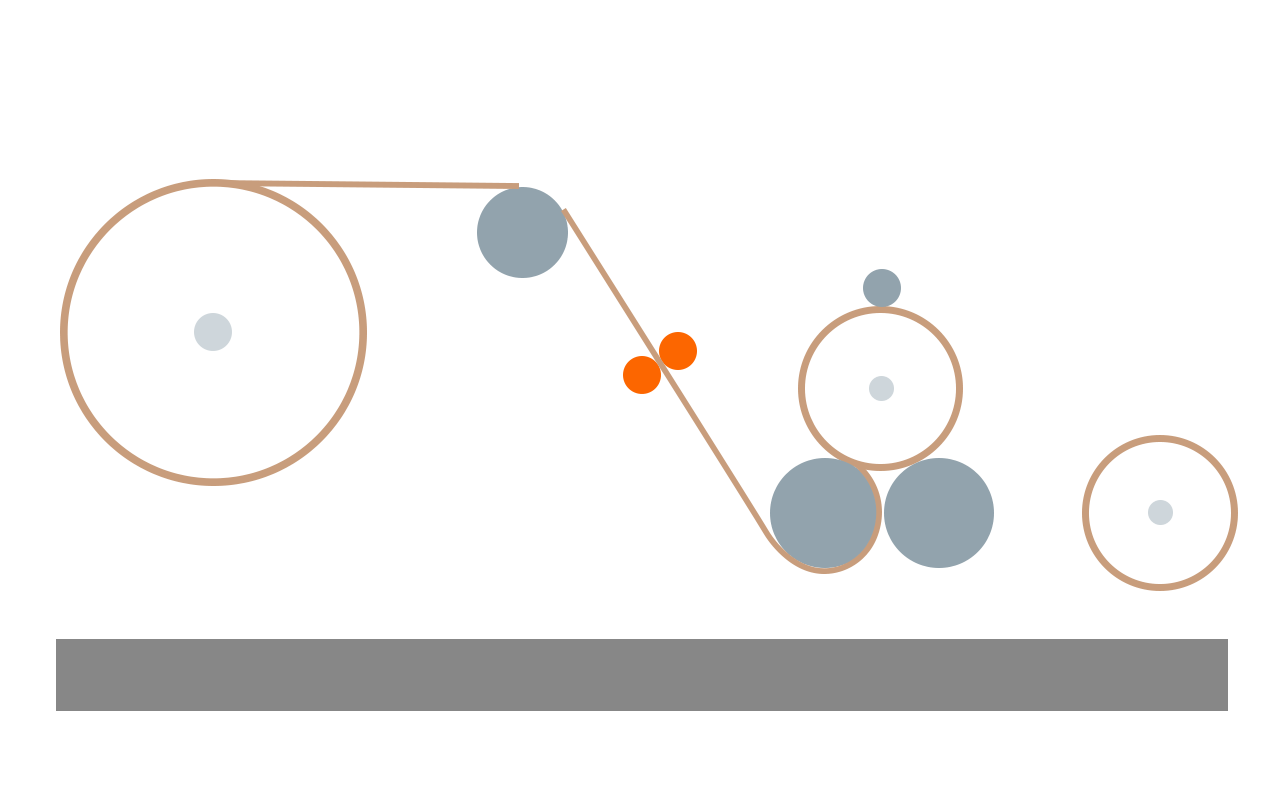

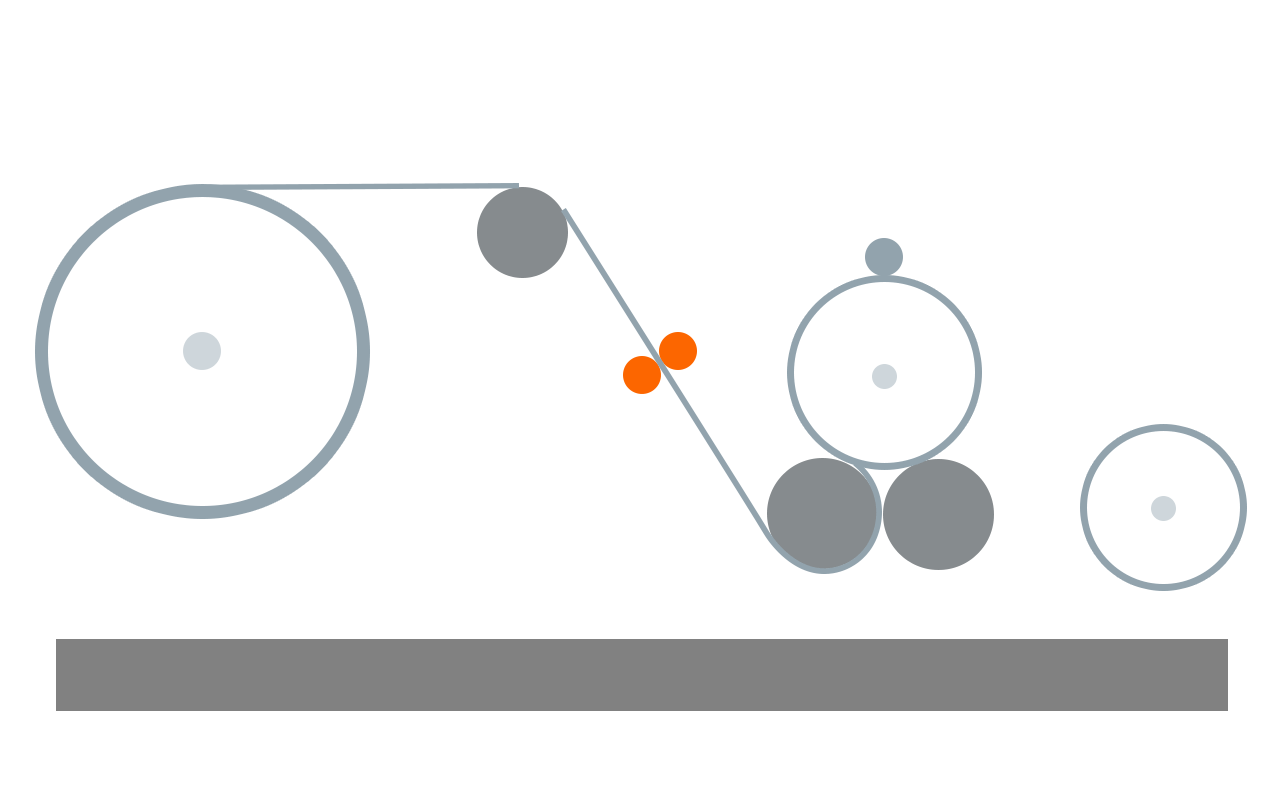

Paper machine winders or paper machine rewinders are used to convert the parent reels coming from the paper or board machine by slitting or cutting off the paper web into narrower rolls called daughter reels. In the beginning of the winding process, the paper web is passed through rolls such as lead roll or sensing roll and then through the slitting station. The slitting station consists of a number of knives that slit or cut the paper web into different sizes of rolls as required by the customer. The nip pressure load required for the optimal performance of the winding tightness of the reels is built by a rider roll. The winder drive system is integrated with the winder to develop high winder performance optimization and productivity with options in terms of reporting and analysis of the paper winder in real time.

Winder performance optimization and digitalization with remote assistance for twin drum winders and paper machines is developed by Scan Machineries Automation Team who are immensely experienced in Siemens Automation, ABB Process Automation, Control Techniques Nidec and Rockwell Automation. Our goal is to provide high quality winding of reels by increasing productivity, maximizing efficiency, speed and quality, resulting in higher competitiveness of Paper Mills in the Pulp and Paper Industry.

Scan Machineries design and manufacture Rewinder and Winder for Kraft Board and Paper Mill, Writing and Printing Paper Mill, and Tissue Paper Mill.

Board and Kraft Winder

Scan Machineries designs, engineers and manufactures Board and Kraft Paper Winders for Paper Manufactures producing high basis weights(gsm) at high design speeds.

Writing and Printing Winder

Scan Machineries designs, engineers and manufactures Writing and Printing Paper Winders for Paper Manufactures producing low basis weights(gsm) at high design speeds.

Tissue Winder Machine

Scan Machineries designs, engineers and manufactures Tissue Paper Winders and Rewinders for Paper Manufactures producing low basis weights(gsm) at high design speeds.

Scan Machineries Winder Features:

- Technical Detials

- Main Features

- Option

- Best For

- Web width up to 7 mtrs

- High speed up to 2000 mpm

- PLC and DCS based control automation

- Auto torque control for both drums

- Auto web tension control by load cells

- Mother roll diameter up to 3.5 Mtrs

- Finished roll diameter up to 2 Mtrs

- Surface coated drums for better web traction

- Auto nip control for rider roll pneumatic/ hydraulic

- Automatic finished reel change

- User friendly knife setting/ replacement

- High tech materials

- Hydraulic / pneumatic reel ejector

- Hydraulic/ pneumatic reel unloader

- Unwind brake generator for power saving

- Calender

- Tension control

- Dust removal system

- Automatic slitter positioning

- Spool brake

- Unwinder spools center drive

Best for high production and low bulk reduction, advanced technology, high quality materials and long-lasting performance

Contact us with your new Paper Mill Winder requirement!

To get a quick reply and quote, fill out the following form. Our sales team will reach out to you shortly.

Paper Mill Turnkey Project

Scan Machineries Undertakes Complete Paper Mill Turnkey Projects for Up to 500 TPD...

GET MORE INFORMATION

Our team is looking forward to undertake your new Paper Mill Winder project.

Contact us : sales@scanmachineries.com